Flygas produce Mechanical Fuel Pumps from many years, and from now will be available at all the Rotax 914 turbocharged or 912Ul-ULS Supercharged, instead at the electrical Pierburg 1 bar pump.

Easy and reliable installation on your Rotax 914 flywheel without modify request so simple installation, this fuel pump it’s supplied with all parts necessary included installation booklet with picture step by step.

After installed, it will can supply gasoline at 1bar of pressure (until 3bar in a case of E.F.I. installed)

This full parts ready to install Fuel Pump is lightweight (only 680Grams, just basically same weight of electrical Pierburg Fuel Pump included wires and switch.)

Finally, we want remember you, All aviation and racing engines have always used and used today , mechanical fuel pumps.

Note: in the latest version of our KIT the distributor valve is no longer needed, thus making the KIT simpler and reducing the total weight…

We are pleased to present the FLYGAS PATENTED KIT , ideal solution for boosting the ROTAX engine of the ULM ultra light airplanes offering electronic injection system as to improve engine capabilities and to reduce operational costs.

This system has been specially designed and calibrated and is complete with all accessories needed for assembly. FLYGAS PATENTED KIT is the result of intense research and precision drawings and calculations.

FLYGAS PATENTED KIT is the result of intense research and precision drawings and calculations. We apply electronic injection as parallel fuel feeding system to the carburettor. The electronic control unit, the pipes, valves, and air intakes undergo efficiency tests and destructive tests to check their performance and reliability.

The kit is customized according to the specific characteristics and needs of the ULM engine and air intake, and is completely calibrated for dosage of the air-fuel mixture under all power delivery conditions.

Price competitive and reliable solution to boost performances and reduce costs!

FLYGAS supplies a product that responds perfectly to the needs of the most demanding customer.

The electronic fuel injection system activated by the FLYGAS PATENTED KIT stands as a parallel unit to the carburetor.

1. For the first time you can have a double fuel injection system electronic fuel injection and carburetor, so will be possible to change in each time, from one system to the other.

2. in any unlikely case of emergency landing you can exchange from electronic fuel injection to the carburetor system and by this simple operation you automatically discharge the high pressure of 3 bar (45 Psi) to the low pressure state as available in the carburetor, i.e. 0.3 Bar (4.5 Psi)

3. No ice forming in the intake manifold.

4. The Stoichiometric ratio will always be the best for the current atmospheric condition and altitude.

5. Absence of vibration regardless of the difference in the opening of carburetor.

6. Possibility of continuing to fly (to 50% of power) even in the case of breakage of a wire command of a carburetor.

7. Equally used cylinders independently from each other. (Currently, especially in supercharged engines, you find the carburetion mostly happens in the thinner cylinder.)

8. Prevention of detonation that it is always possible in the supercharged engine whenever stoichiometric ratio became lean.

*Possibility to supply fully redundant E.F.I. without carburattors.

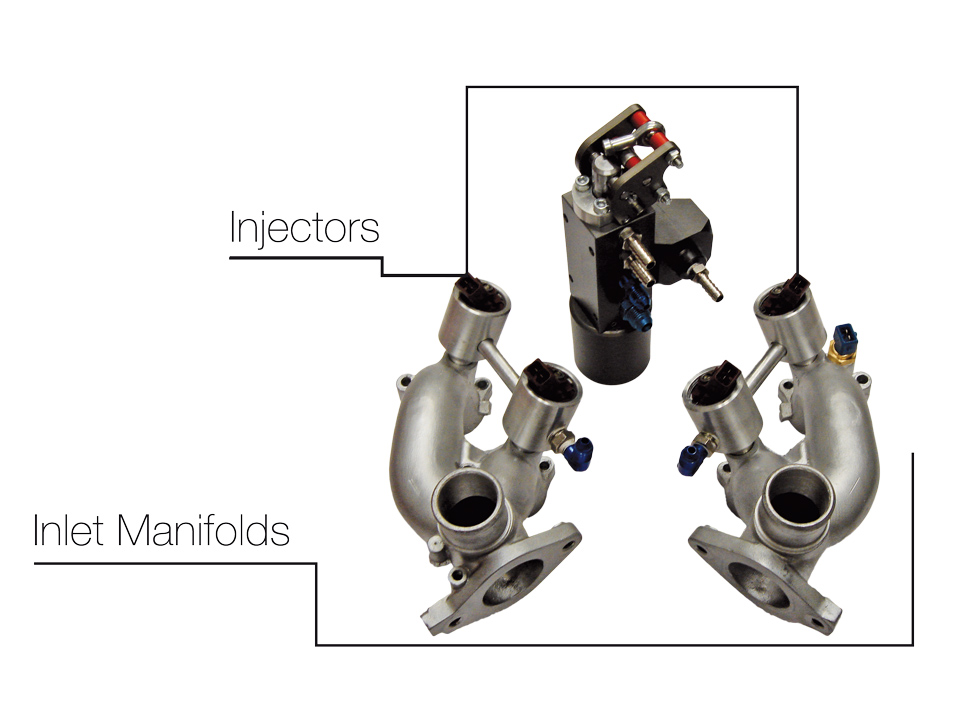

Kit intake manifold

Kit intake manifoldBoost performance with ours intake manifold system.

We are pleased to present the FLYGAS INTAKE MANIFOLDS KIT which improves engine capabilities and reduces operation risk. Ideal solution for boosting the ROTAX engine of the ULM (ultra light airplane.) No need of any modification to install it!

This system has been specially designed and calibrated and is complete with all accessories needed for assembly.

The Ultra-light Airplanes are typically driven by a 4 stroke engine, “Rotax 912” type.

This type of engine is reliable, powerful and is a “reduced weight” motor but it still adopts the two independent carburetor connected with too small pipe.

This original plant has some remarkable defects:

The kit, available for Rotax 912 e Rotax 914, has 9 components:

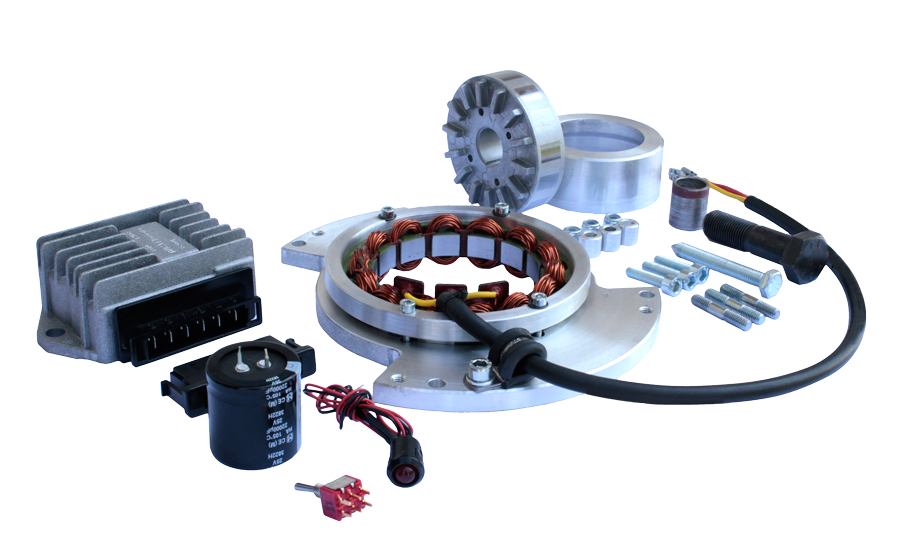

Flygas manufactures and sells the kit alternator dual redundant Rotax

Alternator reverse-phase, 3 wire inner rotor

Power: 180W 12V (also other model 300W and 350W,same installation without belt)

Rpm Max 12000 Rpm

– Heavy and roomy unit : approx 3 kg weigh

– Expensive kit

– Belt driving system

– Modifications required to allocate the additional alternator

– Light and lean: approx 1.5 kg weigh (half of Rotax kit!)

– Not expensive, fairly valued kit

– Without belt driving system but directly set on the engine shaft

– No modification required to allocate the additional alternator

special intercooler for rotax 914 instead of original airbox

special intercooler for rotax 914 instead of original airboxMain features for Rotax 914 Turbo

1. Increase and constant maintenance of the power due to the lower compressed air temperature at engine inlet;

2. Installed instead of the original Airbox, without waste space in the engine compartment

3. Reduction of the risk cutting power on Rotax 914. The lowest air temperatures in carburetors input coincides with an important reduction in the risk of intervention of the TCU control unit. This unit, over the 82 ° C air, open waste-gate valve and discharge boost pressure, avoiding damage to the engine but losing most of the power supplied.

4. Better distribution of mass air to the engine with cylinder banks relative balance without the need to be fitted on the carburetors different main jets between them

5. Assembly “Aircooler” personalized according to your space and on yours overall limits

Flygas has designed and developed a new cylinder head high performance and reliability for the Subaru EA81 engine. The new head is die-cast in G-9-AllSi designed to increase engine performance by increasing the reliability.

Flygas has designed and developed a new cylinder head high performance and reliability for the Subaru EA81 engine. The new head is die-cast in G-9-AllSi designed to increase engine performance by increasing the reliability.

The new cylinder head has the intake and exhaust manifold separate and increase its dimension, two spark plugs per cylinder in opposite position which ensures and improved combustion, increased intake valves diameter, ready for installation injectors of indirect or direct injection and ring valves in special bronze alloy. The performance increase is estimated at +20%.

The installation of the heads and the possible bench test is performed within 30 days of order confirmation.

FlyGas provides technical support for installation and / or for any clarification. It is also possible to arrange for sales assistance and verification of the engine with a data acquisition system for the first test.